Choosing the Right Grease Pump: Tips for Machinery Owners

Maintaining machinery efficiently is critical in any industrial, automotive, or agricultural operation. One of the most important components in ensuring smooth operation and long service life is proper lubrication. A grease pump plays a vital role in this process by delivering the right amount of lubricant to critical machine parts. However, selecting the correct grease pump for your machinery is not always straightforward. This guide will help you make an informed decision.

Understanding the Importance of a Grease Pump

A grease pump is designed to transfer grease from a storage container to lubrication points on machinery. Without proper lubrication, moving parts experience friction, wear, and overheating, which can lead to machine breakdowns and costly repairs. A well-chosen grease pump ensures consistent grease flow, reduces downtime, and enhances the lifespan of your machinery.

Not all grease pumps are the same. Different types of machinery, operating environments, and maintenance schedules require different pumps. Understanding these variables is the first step toward selecting the right solution.

Types of Grease Pumps

There are several types of grease pumps available, and each serves different applications:

- Manual Grease Pumps

Manual grease pumps are operated by hand and are typically suitable for small workshops or machinery with low lubrication needs. They are simple, cost-effective, and reliable but require physical effort to operate. - Electric Grease Pumps

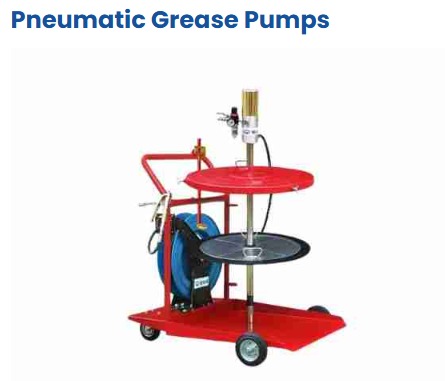

Electric grease pumps are powered by electricity and offer automatic lubrication. These pumps are ideal for high-volume operations where consistency and speed are crucial. They reduce labor costs and ensure precise delivery of grease. - Pneumatic Grease Pumps

Pneumatic pumps use compressed air to deliver grease. These pumps are commonly used in industrial settings where air supply is available. They provide high-pressure delivery and are suitable for heavy machinery requiring consistent lubrication. - Battery-Operated Grease Pumps

Battery-operated pumps combine mobility with convenience. They are perfect for locations where power supply may be limited, offering portability without compromising performance.

Understanding the differences between these types will help you identify which grease pump aligns with your machinery requirements.

Factors to Consider When Choosing a Grease Pump

Selecting the right grease pump depends on several key factors. Ignoring any of these can result in inefficient lubrication, potential machinery damage, and increased maintenance costs.

Type of Machinery

Different machines have varying lubrication needs. Heavy machinery, such as excavators, tractors, or industrial presses, require pumps capable of delivering high volumes of grease at consistent pressure. Smaller machinery, like conveyors or small engines, can function efficiently with a simpler, lower-capacity pump.

Grease Compatibility

Grease comes in multiple types, each designed for specific operating conditions. Some pumps are compatible with thick, high-viscosity grease, while others perform better with lighter lubricants. Ensure the pump you select is compatible with the type of grease your machinery requires.

Flow Rate and Pressure

The flow rate determines how quickly grease is delivered to lubrication points, while the pressure determines how effectively it penetrates bearings and other tight spaces. Industrial machinery often requires high-pressure pumps, whereas lighter equipment may only need moderate pressure. Choosing a pump with the correct specifications ensures efficient lubrication without overloading the system.

Pump Capacity and Reservoir Size

Pump capacity refers to how much grease the pump can handle in a given time, while reservoir size indicates how much grease it can hold before needing a refill. For large-scale operations, a higher capacity pump with a larger reservoir reduces downtime and maintenance efforts. In contrast, small workshops may benefit from compact pumps that are easy to manage.

Delivery Method

Some grease pumps offer centralized lubrication systems, allowing multiple lubrication points to be served from a single pump. Others are designed for direct, one-point lubrication. Consider your machinery layout and the number of lubrication points when choosing a pump to ensure optimal coverage.

Durability and Build Quality

A reliable grease pump should withstand harsh operating conditions, including exposure to dust, moisture, and high temperatures. Look for pumps made of durable materials, with robust seals and corrosion-resistant components. Investing in quality ensures long-term performance and reduces replacement costs.

Ease of Maintenance

A grease pump requires periodic maintenance to function efficiently. Pumps with simple assembly, accessible components, and readily available spare parts are preferable. Ease of maintenance reduces downtime and allows your team to keep machinery running smoothly.

Cost Considerations

While cost is always a factor, it should not compromise performance. Cheaper pumps may save money initially but could fail under heavy use, leading to more expensive repairs. Evaluate the total cost of ownership, including durability, maintenance, and efficiency, rather than just the upfront price.

Installation and Operation Tips

Once you have chosen the right grease pump, proper installation and operation are crucial to maximize its benefits:

- Positioning: Install the pump in an easily accessible location for maintenance and refilling. Ensure it is stable and secure.

- Hose and Fittings: Use hoses and fittings compatible with the pump to prevent leaks and maintain consistent pressure.

- Regular Monitoring: Check grease levels, flow rate, and pressure regularly to ensure the system functions correctly.

- Follow Manufacturer Guidelines: Adhering to the manufacturer’s instructions ensures optimal performance and prolongs the pump’s lifespan.

Common Mistakes to Avoid

Choosing a grease pump without proper assessment can lead to common issues, including:

- Selecting a pump with insufficient pressure or flow for the machinery

- Using incompatible grease types, leading to clogs or inefficient lubrication

- Ignoring maintenance requirements, causing premature pump failure

- Overlooking the number of lubrication points, resulting in uneven grease distribution

Avoiding these mistakes ensures that your machinery receives consistent lubrication, reducing wear and extending operational life.

Benefits of the Right Grease Pump

Investing time and effort in selecting the right grease pump brings several benefits:

- Improved Machine Longevity: Proper lubrication reduces friction and wear, extending the life of components.

- Reduced Downtime: Consistent grease delivery prevents unexpected breakdowns and keeps machinery operational.

- Cost Savings: Efficient lubrication reduces repair costs and energy consumption.

- Enhanced Safety: Well-maintained machinery operates more reliably, reducing the risk of accidents.

Conclusion

Choosing the right grease pump is a critical decision that directly impacts the performance, reliability, and longevity of your machinery. By understanding the types of pumps, assessing your machinery needs, and considering factors like grease compatibility, pressure, flow rate, and durability, you can select a pump that ensures optimal lubrication. Avoiding common mistakes and adhering to proper maintenance practices will help you maximize the benefits of your investment.

In today’s fast-paced industrial environment, a high-quality grease pump is not just a convenience—it is an essential tool for keeping machinery running smoothly, efficiently, and safely.